The strength of ultrasonic welding is not enough, and […]

The strength of ultrasonic welding is not enough, and the treatment method of ultrasonic welding is not strong

If it is an old tooling, stick the product on the welding head first, and observe whether the gap between the product and the welding head is too large to determine whether the welding head is worn or not; if it is a new tooling, please scan with the welding head. Observe his frequency, power, and graph, and make sure that the welding head has no problem.

Use a caliper to check the size of the welded product, and then debug according to the difference of the data:

(1) The size of the welded area is too large, and the size of other positions is OK. Please adjust the horizontal plate and raise the corresponding position. If adjusting the horizontal plate has a greater impact on other positions, you can paste thin tin foil on the tooling where the welding is not strong. ;

(2) The overall height of the product is too large. Please modify the welding parameters and increase the welding depth. After the modification, if the defect can be eliminated, please observe whether there is any flash in other positions;

(3) The size is OK, please adjust the following parameters: increase the amplitude, reduce the air pressure, and slow down the descent speed of the welding head. If the defect can be eliminated, please confirm whether there is flash in other positions;

(4) The size is OK and the welding is still not strong after the above measures, or the size is too small after welding and the welding is still not strong. Please contact the process and structural design to modify the height of the welding rib or make other corresponding modifications.

Recently, such a problem has been discovered. In order to get off work early, some workers adjust the data privately, adjust the air pressure and welding speed to unreasonable states to speed up the welding speed. If there is a manager, the data will be restored to normal. Adjusted back again, causing the product to go well and not well. Therefore, when the workshop reports that some products are leaking and some are not leaking, if the tooling and raw materials are confirmed to be OK, it can be considered that this has happened, and the workshop management personnel should be asked for assistance to prevent such incidents from happening.

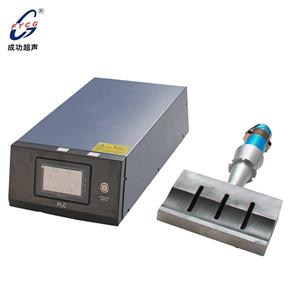

If it is a new ultrasonic welding mold, the output amplitude of the ultrasonic must be considered. Is the ultrasonic mold design unreasonable, or the ultrasonic welding machine itself has low power and low amplitude output. When you use a machine with a smaller power and amplitude to weld one Larger products or products with harder materials to weld will have weak welding.

What specific product, what material, what power and amplitude ultrasonic welding equipment needs to be used, which requires experienced technicians to judge, we provide free consultation in this regard!

Our company has rich experience in dealing with difficult-to-weld materials and demanding products.