The phenomenon of ultrasonic cavitation in a liquid is […]

The phenomenon of ultrasonic cavitation in a liquid is called sonochemistry, and this type of equipment is collectively called sonochemical equipment. Sonochemical applications can be divided into: dispersion, catalysis, cell disruption, cleaning, emulsification and homogenization, extraction, etc.

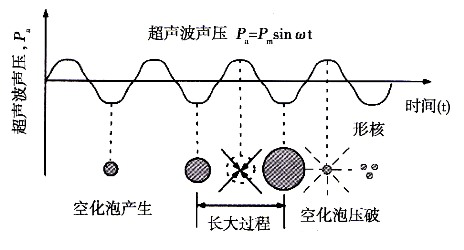

Ultrasonic dispersion refers to the process of dispersing, pulverizing and de-aggregating particles in the liquid through the "cavitation" effect of ultrasonic waves in the liquid using liquid as a medium.

Ultrasonic dispersion equipment is an application of sonochemical equipment, which can be used for water treatment, solid-liquid dispersion, de-agglomeration of particles in liquid, and promotion of solid-liquid reaction.

The phenomenon of ultrasonic cavitation in a liquid is called sonochemistry, and this type of equipment is collectively called sonochemical equipment. Sonochemical applications can be divided into: dispersion, catalysis, cell disruption, cleaning, emulsification and homogenization, extraction, etc.

Ultrasonic dispersion refers to the process of dispersing, pulverizing and de-aggregating particles in the liquid through the "cavitation" effect of ultrasonic waves in the liquid using liquid as a medium.

Ultrasonic dispersion equipment is an application of sonochemical equipment, which can be used for water treatment, solid-liquid dispersion, de-agglomeration of particles in liquid, and promotion of solid-liquid reaction.

The graphene ultrasonic pilot cycle machine is generally used to simulate the pipeline ultrasonic processing process, the ultrasonic power is 1000W to 3000W, and the volume is 5L. The main configuration consists of an ultrasonic host, a digital control drive power supply, a circulating reactor, and a peristaltic pump. A single industrial application unit simulates the industrial environment and determines the amplitude, pressure, temperature and other parameters of the industrial application.

The graphene ultrasonic production line is mainly used for mass production of graphene, and the annual output (8h/day) can reach 10 tons to 300 tons. The rated power of a single ultrasonic set is 3000W/set, and the conventional production line is three-in-one. In addition, an applicable plan can be worked out according to the working conditions of the site. The main configuration consists of ultrasonic emission system, ultrasonic numerical control power supply, ultrasonic control system assembly, ultrasonic reactor assembly, frame and pipe accessories. Multiple sets of series and parallel structures realize continuous industrial production of pipelines. According to the application, the composite ultrasound application of different processes can be realized.

Hangzhou Chenggong Ultrasonic Equipment Co., Ltd. was founded in 1995. It is a professional manufacturer engaged in ultrasonic application research, development and production of high-power ultrasonic transducers in China. The company's main products are transducers, ultrasonic drive power supplies, etc. These products are widely used in sonochemistry, plastic welding, metal welding, rubber cutting, non-woven fabric welding and other fields as the core key components of the power ultrasonic application industry.